Why You Should Choose Waterproof Lithium Batteries

Water has always been both a giver and taker in modern industry. It cools, cleans and sustains, yet it also corrodes, infiltrates and destroys. In the age of electrification, lithium batteries power many devices. These include eBikes, AGVs, robots, drones, marine systems, and industrial tools.

However, moisture has become a common cause of battery failures and safety issues. As global demand shifts toward reliable, outdoor-ready energy solutions, waterproof lithium batteries are evolving from an optional upgrade to a fundamental requirement.

This news feature looks at why waterproof lithium batteries are important. It explains how water impacts regular battery packs.

1. The Hidden Enemy: Why Water Is So Dangerous for Lithium Batteries

At first glance, a drop of water seems harmless. Inside a lithium battery, chemicals, electrons, and tiny protection circuits work together. Moisture acts like an unwanted guest that disrupts everything.

When water penetrates an unprotected battery pack, three major risks arise:

1.1 Internal Short Circuit

Moisture can get into a battery and go past insulation layers. This allows current to flow where it shouldn’t. A short circuit is essentially a runaway train that the battery’s protective systems struggle to stop.

1.2 Corrosion and Long-Term Degradation

Even if no short circuit occurs, water vapor alone can corrode BMS components, nickel strips, electrodes and weld points. Corrosion slowly eats performance from the inside out, shortening cycle life and degrading energy output.

1.3 Thermal Events and Safety Hazards

In severe cases, water intrusion can trigger reactions that generate excess heat, gas or swelling. In worst-case scenarios, this leads to smoke, leakage or fire. Structural integrity issues, poor sealing, or insufficient waterproof protection often cause most publicized lithium battery accidents.

In outdoor environments—rain, humidity, puddles, cleaning water, snow melt—these risks multiply. Equipment that operates in coastal regions or tropical climates faces even greater threats.

This is precisely why waterproof lithium batteries have become essential.

2. The Rise of Waterproof Lithium Batteries in the Global Market

Global electrification is no longer a trend; it is the new blueprint for how modern industries operate. As people increasingly deploy outdoor and semi-outdoor equipment, they now consider waterproof features mission-critical.

2.1 eBikes and Light Electric Vehicles

eBikes travel through rain, mud, snow and daily washing. A non-waterproof battery is a ticking time bomb for riders and manufacturers alike. Leading European and North American vehicle standards now emphasize waterproof protection as a key safety indicator.

2.2 AGVs and Industrial Automation

Warehouses, logistics centers and factories often undergo routine floor cleaning, sanitation and exposure to condensation. Manufacturers must harden AGV batteries to ensure they survive these environments without downtime.

2.3 Robotics and Drones

Service robots, inspection robots and outdoor drones frequently work in unpredictable environments. You must fortify batteries exposed to mist, moisture, dew, or accidental splashes accordingly.

2.4 Marine and Offshore Equipment

Waterproof lithium batteries are indispensable for navigation devices, buoys, underwater drones and unmanned boats, where waterproofing isn’t a convenience but a survival requirement.

2.5 Medical and Emergency Devices

Medical mobility devices and emergency equipment must remain safe and stable even in environments involving cleaning agents, disinfectant spray or unexpected fluid exposure.

The market is changing, and First Power is moving at the front of this transformation.

3. How Shenzhen First Power Builds Its Waterproof Lithium Batteries

A waterproof battery is not created by simply adding a sealant or thicker plastic. True protection requires system-level engineering. Shenzhen First Power Energy Co., Ltd. integrates waterproof design across structure, electronics, testing and manufacturing.

The company’s approach includes several layers of defense that work together like a coordinated security team.

4. Structural Innovation: Building a “Waterproof Fortress” Around Each Cell

First Power designs battery packs as if each were a miniature fortress protecting valuable energy reserves.

4.1 Reinforced, Thickened Casing

The company uses high-density PC/ABS housings, aluminum shells, or customized composite enclosures depending on application. Each casing is engineered with:

Enhanced impact resistance

Temperature stability

Warp-free structural integrity

Anti-crack performance for long-term outdoor use

4.2 Precision-Sealed Enclosure Joints

Where many packs rely on simple snap closures or adhesive strips, First Power applies multi-channel sealing techniques:

High-temperature silicone gaskets

Seam-free structural interfaces

Multi-layer closure mechanisms

Internal waterproof membranes for sensitive circuits

This ensures no water ingress through the housing’s micro-openings.

4.3 Internal Support Pillars and Reinforcement Ribs

Inside the pack, structural pillars create an internal skeleton that prevents deformation under pressure, vibration or mechanical stress. This prevents small cracks that could allow moisture to seep in.

5. Electronic Protection and Smart BMS Safeguards

Waterproofing is not only physical. First Power reinforces its electronic protection systems to prevent moisture-induced malfunctions.

5.1 Conformal Coating for PCBs

All critical BMS components receive an insulating protective layer resistant to:

moisture

corrosion

salt fog

dust

This coating ensures reliable function even in humid or coastal environments.

5.2 Moisture-Resistant Connectors and Potting

Electrical connectors and joints are sealed with high-grade potting compounds, preventing water from bridging any contact points.

5.3 Multi-Layer Safety Architecture

First Power BMS systems include:

Overcharge and over-discharge protection

Short circuit prevention

High-current limiting

Temperature monitoring

Fault diagnosis algorithms

When combined with waterproof design, these create a safety ecosystem that prevents incidents before they occur.

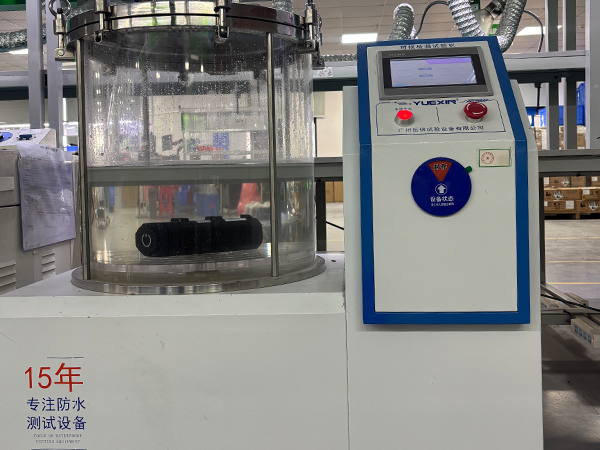

6. Waterproof Certification and Testing Standards

First Power puts its waterproof batteries through a battery of stress tests that mimic real-world extremes.

6.1 IPX Waterproof Standards

Depending on application requirements, batteries undergo tests targeting:

IPX5: Water jets

IPX6: High-pressure streams

IPX7: 1m submersion

IPX8: Extended underwater operation

Customers can request custom waterproof levels based on their industry.

6.2 Salt Spray Testing

Coastal, marine and winter environments contain corrosive salt mist. First Power performs salt spray testing to ensure no degradation of metal components or PCBs.

6.3 Humidity Chamber Testing

Batteries are tested under 95% RH environments to simulate tropical climates and constant humidity exposure.

6.4 Pressure and Vacuum Leakage Tests

These tests check whether the battery enclosure can maintain seal integrity under varying atmospheric conditions.

First Power combines real-world situations with engineering skill. This ensures that each pack has a strong “shield” against water intrusion.

7. Application Case Studies: Where Waterproof Batteries Excel

7.1 Outdoor eBike OEM Partner

A European OEM required an IPX7-rated down-tube battery capable of daily washing and rain operation. First Power engineered a waterproof structure with reinforced housing and a redesigned silicone-sealed joint system. Field testing showed zero leakage after 120+ wash cycles.

7.2 AGV Systems in High-Humidity Warehouses

A logistics facility located in Southeast Asia faced frequent battery corrosion issues because of indoor humidity. First Power’s sealed AGV battery pack eliminated failure incidents and extended replacement cycles by over 40%.

7.3 Marine Navigation Equipment

First Power provided IPX8-rated lithium packs for a client that makes ocean monitoring devices. These packs have anti-corrosion coatings and double-layer PCB protection. The packs demonstrated stable performance even after prolonged exposure to saltwater.

Waterproofing is not just a safety feature. It also adds value by making equipment last longer and work better.

8. The Business Case: Why Manufacturers Should Upgrade to Waterproof Packs

Waterproof lithium batteries offer measurable economic and operational benefits for manufacturers.

8.1 Fewer Returns and Warranty Claims

Water penetration is one of the top causes of battery malfunction. Waterproofing reduces defects and warranty expenses significantly.

8.2 Extended Device Lifespan

Stable performance over time helps customers perceive higher product quality and reliability.

8.3 Competitive Advantage

In markets like Europe and North America, waterproof battery capability is increasingly becoming part of regulatory and OEM requirements. Early adoption gives manufacturers a strong competitive edge.

8.4 Consistent Performance in Harsh Environments

Downtime caused by battery issues can interrupt logistics operations, manufacturing workflows or transportation services. Waterproof packs minimize unexpected interruptions.

8.5 Enhanced Safety Reputation

Safety is a brand's foundation in the energy industry. Products equipped with waterproof batteries from a certified manufacturer like First Power strengthen consumer trust.

9. First Power’s 12-Year Technical Accumulation in Battery Engineering

Shenzhen First Power Energy Co., Ltd. brings over a decade of R&D and manufacturing experience to the field. The company integrates:

Advanced cell matching

Laser welding

Automated production lines

International certifications (UL, IEC, CE, PSE, KC, UN38.3)

Custom BMS development

OEM/ODM services

This expertise enables First Power to build waterproof solutions tailored for global equipment manufacturers with high reliability demands.

The company has delivered lithium battery packs to customers in over 150 countries, powering mobility systems, robots, tools, medical devices and industrial equipment worldwide.

10. The Future: Waterproof Lithium Batteries as a New Industry Standard

As industries shift toward electrification and outdoor-ready smart devices, waterproof batteries will no longer be optional. They will be the new baseline for any serious manufacturer. Extreme weather patterns, coastal expansion, personal mobility growth and AGV automation will all accelerate demand.

Shenzhen First Power Energy Co., Ltd. positions itself at the forefront of this movement by delivering waterproof battery solutions engineered for safety, durability and global application versatility.

The company has a strong mission. They want to ensure that every watt delivered to customers is safe. It should also be stable and ready for real-world challenges.

In a time when energy powers modern devices, waterproof lithium batteries act as armor. They help keep that energy strong.

Related articles

-

2025-12-02

Why Lithium Batteries Catch Fire...