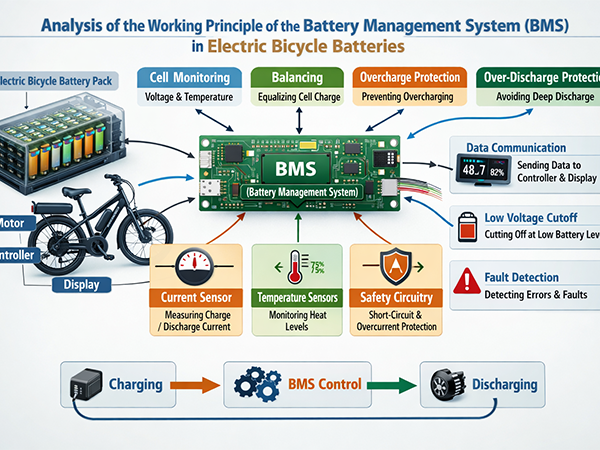

Analysis of the Working Principle of the Battery Management System (BMS) in Electric Bicycle Batteries

In an electric bicycle battery system, if the battery cells are the "energy heart," then the Battery Management System (BMS) is the "brain and guardian" of the entire battery system.

As electric bicycles evolve towards higher power, longer range, and higher safety standards, the BMS is no longer a simple protection module, but a critical core component that determines the safety, stability, and lifespan of the battery.

This article will analyze the working principle and core value of the BMS in electric bicycle batteries.

Part 1. What is a Battery Management System (BMS)?

A **BMS (Battery Management System)** is an electronic system used to monitor, control, and protect the battery pack. Its main functions are:

Real-time monitoring of battery status

Preventing the battery from operating under abnormal conditions

Coordinating safe interaction between the battery and the entire vehicle system

In electric bicycles, the BMS is not an optional add-on component, but a fundamental configuration for the safe operation of lithium batteries.

Part 2. Core Working Principle of Electric Bicycle BMS

From an engineering perspective, the BMS operates around three levels: **"Monitoring → Judgment → Control"**.

1. Real-time Monitoring: Understanding the Battery's "Vital Signs"

The BMS continuously monitors the following key parameters through sensors and sampling circuits:

Individual cell voltage

Total battery pack voltage

Charging and discharging current

Battery temperature (single point or multiple points)

This data forms the basis for the BMS to determine the battery status.

2. Status Judgment: Identifying Risks and Abnormalities

Based on the collected data, the BMS compares it with preset safety thresholds, such as:

Whether there is a tendency for overcharging

Whether it is approaching the over-discharge critical point

Whether there is an abnormally high current

Whether there is an abnormal temperature rise

Once outside the safe range, the BMS will immediately enter the protection logic.

3. Control Execution: Active Intervention to Prevent Risk Escalation

When an abnormality is detected, the BMS will use MOS transistors or relays to:

Cut off the charging circuit (to prevent overcharging)

Cut off the discharging circuit (to prevent over-discharging or overcurrent)

Limit output power

Send an abnormal signal to the entire vehicle system

This active intervention mechanism is an important line of defense to prevent thermal runaway in lithium batteries.

Part 3. Main Protection Functions of Electric Bicycle BMS

In First Power's electric bicycle battery solutions, the BMS typically features the following core protection functions:

Overcharge protection: Prevents cell voltage from exceeding the safe limit.

Over-discharge protection: Avoids deep discharge that affects cell lifespan.

Overcurrent protection: Prevents high currents from damaging the battery and circuitry.

Short-circuit protection: Provides rapid response to external or internal short circuits.

Temperature protection: Automatically limits or shuts off power at high or low temperatures.

These protections do not exist in isolation but operate collaboratively, forming a multi-layered safety system.

Part 4. How Does BMS Affect Battery Lifespan and Consistency?

Many people believe that BMS is only related to "safety," but in practical applications, BMS also profoundly affects battery lifespan and consistency.

1. Voltage management, delaying cell aging

Reasonable charge and discharge voltage control can significantly reduce cell structural damage.

2. Current control, reducing thermal stress

Avoiding frequent high-current surges helps maintain long-term cell stability.

3. Balancing management, improving overall consistency

Some BMS systems support passive or active balancing, reducing the impact of individual cell differences on overall performance.

Part 5. First Power's BMS Design Philosophy

At First Power, we believe there is no "universal BMS," only "BMS tailored to specific application scenarios."

For electric bicycle applications, First Power focuses on the following in its BMS solution design:

Matching motor power and controller

Actual riding load and operating conditions

Waterproof, shockproof, and long-term reliability

Communication and compatibility with the entire vehicle system

Through a systematic design of cells + structure + BMS + manufacturing process, we ensure the safety and stability of the battery in real-world usage environments.

Part 6. Professional Value for Vehicle Brands

For electric bicycle manufacturers, choosing a mature and reliable BMS solution means:

Lower risk of safety incidents

More stable vehicle performance

More controllable after-sales and warranty costs

Higher market and channel trust

First Power not only provides battery products but also offers BMS strategies and technical support tailored to the entire vehicle system.

Part 7. BMS is the Underlying Logic of Battery Safety

The safety of electric bicycle batteries is never determined by a single parameter, but rather is a manifestation of systems engineering. And the BMS is the core control center in this system. First Power will continue to provide safe, reliable, and long-term electric bicycle battery solutions to global customers through its mature BMS (Battery Management System) solutions and rigorous manufacturing system.