9 Steps to Manufacturing a High-Quality Battery Pack

Battery packs are used in many electronic devices, from electric vehicles to portable equipment. Ensuring consistent performance, reliability, and service life requires a detailed manufacturing process. Each stage contributes to the quality of the final product.

Here is a summary of 9 key steps in the production of a battery pack.

Step 1: Raw Material Selection

The first step is selecting raw materials.

Cells, connectors, and battery management system (BMS) components must meet specifications for energy density, thermal stability, and conductivity. Using materials that meet design requirements is essential to achieve consistent performance and operational reliability.

At Shenzhen First Power Energy Co., Ltd. (FirstPower):

Cells are inspected internally and tested for consistency.

Connectors are designed to endure repeated insertions.

BMS components are produced under controlled processes to maintain functionality.

Step 2: Cell Sorting and Matching

Cells are sorted and matched according to voltage, capacity, and internal resistance.

Even cells from the same batch may differ slightly. Matching cells with similar characteristics helps ensure balanced charging and discharging, maintaining uniform pack performance and lifespan.

Example from a typical TP6068 battery pack:

Cells from the same production batch

Voltage difference ≤ 5 mV, internal resistance ≤ 2 mΩ

Matched cells ensure consistent operation across the pack

Step 3: Battery Management System (BMS) Integration

The BMS monitors and controls the battery pack, maintaining operational consistency.

Integration involves:

Connecting sensors to monitor voltage, current, and temperature

Configuring circuits to manage charging and discharging cycles

Testing functionality to confirm proper operation under normal conditions

Step 4: Battery Module Assembly

Cells are grouped into modules to achieve the required voltage and capacity.

Precise assembly ensures secure connections, typically through welding or soldering. Module integrity is critical for safe and consistent operation.

At FirstPower, welding processes follow controlled standards:

Consistent weld quality

Mechanical strength verification for reliability

Step 5: Pack Assembly

Modules are assembled into the final battery pack configuration.

Connections are secured to maintain stable current flow, and the structure is reinforced for operational stability. The assembly ensures the pack meets design specifications for its intended application.

Step 6: Enclosure and Structural Design

The enclosure provides physical protection, supports heat management, and maintains a compact design.

Materials are selected to balance strength, weight, and heat dissipation. The structure is designed to handle operational and environmental conditions.

Step 7: Encapsulation and Sealing

Encapsulation and sealing provide additional protection against moisture, dust, and mechanical impacts.

Sealing helps prevent external contaminants from affecting performance. Many FirstPower packs meet IP67 standards for operation in various conditions.

Step 8: Safety Testing and Quality Control

Battery packs undergo testing to ensure they meet performance and safety standards.

Tests may include:

Electrical performance assessment

Thermal evaluation

Vibration and impact tests

Each pack is evaluated according to international standards such as CE, FCC, UL2271, IEC62133, and EN15194.

Step 9: Final Inspection and Testing

Final inspections verify that components are correctly assembled and performance specifications are met.

Testing may include:

Capacity and cycle assessments

Communication and functional checks

End-of-line quality control

Battery packs that meet these requirements are approved for deployment in devices and systems.

Conclusion

Manufacturing a battery pack requires careful attention at each stage, from material selection to final inspection. Following these steps ensures that battery packs perform consistently and operate reliably across their service life.

FAQ

Q1: What are the main advantages of lithium-ion battery packs compared to lead-acid batteries?

A: Lithium-ion batteries typically have higher energy density, longer service life, and lighter weight, suitable for applications such as electric vehicles, energy storage systems, and portable equipment.

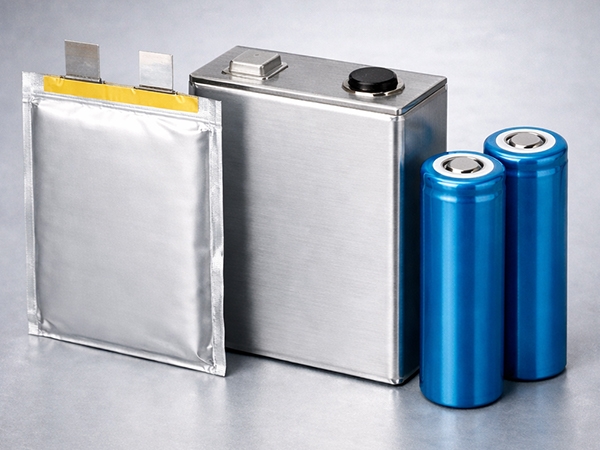

Q2: How do pouch cells affect battery pack performance?

A: Pouch cells offer flexible packaging and lightweight design, which can improve energy density and efficiency in battery packs.