How to Prevent Thermal Runaway in Electric Bicycle Batteries?

With the widespread use of electric bicycles in urban commuting, leisure riding, and delivery services, battery safety has become a top concern for users, brands, and regulatory authorities.

Among these concerns, thermal runaway in lithium batteries is critical. Once it occurs, it can not only damage the battery but also pose serious safety risks.

This article provides a professional guide on how to prevent thermal runaway in e-bike batteries and ensure safe riding.

1. What is Thermal Runaway?

Thermal runaway refers to the uncontrolled chemical reaction inside a battery under conditions like overcharge, over-discharge, short circuit, or abnormal temperature, which generates excessive heat and may lead to:

Battery swelling or rupture

Smoke or fire

Complete battery failure

Common causes include:

Poor quality or inconsistent cells

Improper charge/discharge management

Insufficient heat dissipation or high-temperature environment

External mechanical damage

At FirstPower, we prioritize minimizing thermal runaway risks in every battery design.

2. Choose High-Quality Cells to Reduce Thermal Risk

The battery cell is the core component, and its quality directly affects thermal stability. FirstPower recommends:

Use certified, high-quality lithium cells (cylindrical, prismatic, or pouch type)

Strictly screen cell consistency to ensure uniform voltage and internal resistance across the pack

Conduct high-temperature aging and cycle tests to identify potential thermal risks

High-quality cells, combined with scientific design, significantly reduce the probability of thermal runaway.

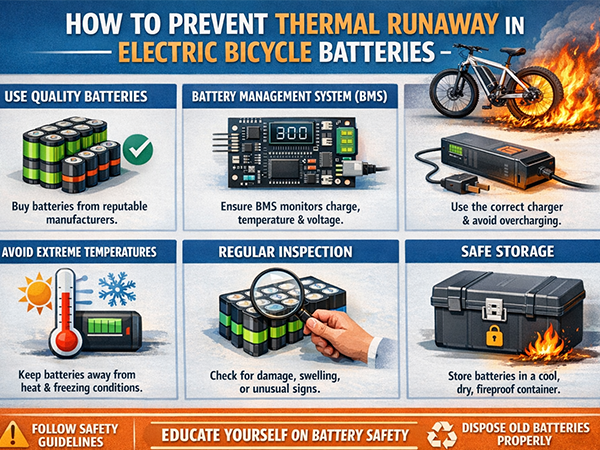

3. Intelligent Battery Management System (BMS) is Essential

A BMS is the “nervous system” that prevents thermal runaway, with key functions including:

Overcharge protection – prevents excessive voltage

Over-discharge protection – avoids deep discharge damage

Overcurrent and short-circuit protection – quickly cuts off abnormal currents

Temperature monitoring – triggers safety cutoff when cells overheat

FirstPower provides customizable intelligent BMS solutions that monitor battery status in real time to prevent heat accumulation.

4. Optimize Structural Design and Thermal Management

Electric bike batteries are exposed to environmental stress and vibration during riding. Proper thermal management is critical:

Design effective heat dissipation channels for quick heat release

Use high thermal conductivity materials and insulation structures to reduce local overheating

Shock-proof mounting to prevent internal short circuits from impacts

FirstPower integrates protection and heat management in battery housing and internal design, ensuring stability even under high-load operation.

5. Safe Charging and Usage Practices

Beyond design and manufacturing, proper usage is equally important:

Use the original or certified charger

Avoid charging/discharging in extreme environments

Regularly check battery housing, connectors, and voltage

FirstPower recommends paying attention to temperature alerts and charging warnings to handle anomalies promptly.

6. Manufacturing Process and Quality Control

Thermal runaway can also arise from poor production processes. FirstPower ensures safety through:

Standardized automated welding and assembly

Complete battery pack aging tests

Strict outgoing inspection standards

This guarantees that every e-bike battery leaving the factory is safe and reliable.

7. Conclusion

While thermal runaway is an inherent risk in lithium batteries, it can be effectively prevented through high-quality cells, intelligent BMS, scientific thermal management, strict production processes, and proper usage.

FirstPower always upholds:

Safety first, long-lasting performance, and reliable quality

We provide customers with highly safe and high-performance electric bicycle battery solutions, ensuring every ride is safe and dependable.